Bi-directional Load Test

Bi-directional Load Test

The bi-directional load test is the only alternate maintained load testing method that uses a time and space saving approach of loading the foundation unit’s resistance from the mid-pile or near-toe position instead of top-loading.

The bi-directional load test method shall conform to ASTM D8169-18 which specify:

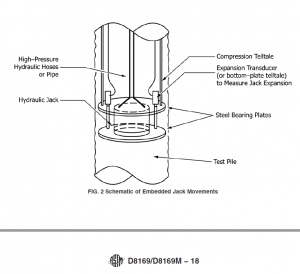

3.2.7 jack assembly, n—one or more bi-directional jacks arranged together with any plates to act in parallel symmetrically around a central axis, which will be embedded within a deep foundation element to apply a bi-directional compressive load aligned with the central axis of the deep foundation element.

The ability of this load test method to embed the sacrificial hydraulic jack near to the toe of the foundation unit enabling the skin friction and end bearing of the foundation unit to be assessed separately. Unlike conventional maintained load test which load is apply from the top, the skin friction and end bearing is usually not distinguishable because the foundation unit is loaded as whole, and also due to the fact that large movement (usually 10% of the pile size) is required to mobilise the end bearing which may not practically achieved in conventional maintained load test.

Bi-directional load test performs similarly as to the conventional maintained load test with two important static features:

1) ability to apply the test load in stages

2) ability to maintain loading over specified duration. Due to these features, the static performance and soil behaviour of the foundation unit tested could be analyzed for comparison with the conventional maintained load test.

As in conventional maintained load test, bi-directional test pile instrumented with strain gauge provides essential information on the soil parameter, i.e., static load distribution and subsequent computation of mobilised unit skin friction and unit end bearing.

Bi-directional load testing is carried out via fully automated recording, by using displacement and pressure transducer which the readings are logged by data logger and display live on the PC at every minute interval. In the past years, the performance of bi-directional load test is often compared with conventional maintained load test, and with Finite Element Method (FEM). Many papers have cited good agreement between the comparison of performance of the two load test methods, and also comparison with FEM modelling. The significant advantages of bi-directional load testing method are:

Engineering Solution – being the only other alternative maintained load test, single-level bi-directional test performs similar to the conventional maintained load test. The interpretation of equivalent load settlement provide close result compares to the direct pile head settlement obtained from conventional maintained load test.

On a multi-level bi-directional test, distinct elements of the test shaft can be singled out for testing.

Practicality – Bi-directional load test is a mobile test system as the fabrication of jack assembly to reinforcement cage only requires minimum space on-site. This allows great flexibility on the test pile location and can be adopted in whatever type of project, such as flyover, bridges, elevated highway, pile with deep cut-off level, offshore, and etc.

Bi-directional load test can be conducted on test pile as small as 0.8m to 3.0m, with test load from 195 tonnes to more than 11,000 tonnes.

Attainment – Bi-directional test piles can and have been cast successfully if bored hole stability is maintained through proper construction technique. Tremie casting from bottom will ensure any small fraction of loose sands or particles staying within the limit is pushed around the bottom jack assembly by the concrete, as concrete density is much higher and denser than those loose particles. Throughout the curing period, initial wet concrete will fully bond with the whole hydraulic jack assembly in its hydration process to dry concrete.

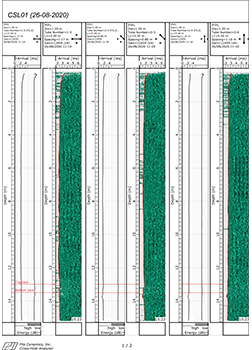

Bi-directional test pile can always be installed with sonic logging tubes to clarify doubts and allay concerns on the pile integrity. Past sonic logging test performed on numerous bi-directional test piles have shown satisfactory pile integrity when the bored hole stability is met during construction.

Low Risk – By eliminating the external reaction, bi-directional load test offers much peace of mind, as the intrinsic risk of collapse in conventional maintained load test which had happened is totally eliminated. As such, bi-directional load testing method represents the best safe construction practices.

Time Efficiency – Bi-directional load test system is quick to deploy and to assemble on-site. A typical deployment only requires several days of on-site installation without hindering of other site activities. Testing can commence immediately after sufficient concrete curing time.

Structural Integrity – The correct bi-directional load test system should allow any working pile to be successfully grout back after the test. This ensure the working pile’s compression load is able to transfer from the upper jack pile’s segment to beneath the lower jack pile’s segment. Failing which, the structural integrity of the pile is compromised due to this testing method.

The two areas which require grouting are:

1) the embedded jack(s) itself

2) the horizontal crack at the plane of the jack’s expansion.

Our bi-directional load test system comprises:

1) two hoses for each jack which allow dispel of water from one hose when high strength cement grout is pump in from another hose, as water is incompressible.

2) Pre-installed grouting pipe spanning through the pile’s cross section at the plane of jack expansion allows the concrete horizontal crack to be successfully grout back. This is only made possible through the use of steel plate in compliance with ASTM D8169-18.